Before choosing a type of solenoid valve, sufficient information about the application must be gathered. This guide describes the key parameters for solenoid valves.

These are the most important guidelines when selecting a solenoid valve. Keep these guidelines in mind before choosing a valve.

Solenoid valves are very sensitive to dirt and only work with clean liquids or air.

Note that indirectly controlled solenoid valves require a permanent pressure differential of around 0.5 bar to function properly. Therefore, you can not use indirect operated valves in a closed circuit or systems with a low inlet pressure. Direct and semi-direct operated valves operate with a pressure differential from 0 bar.

Make sure that the used medium and temperature are compatible with the materials of the valve, such as body and the seal materials.

Solenoid valves open and close fast (between around 10 and 1000 ms). Improper use can cause pressure transients in the system (water hammer).

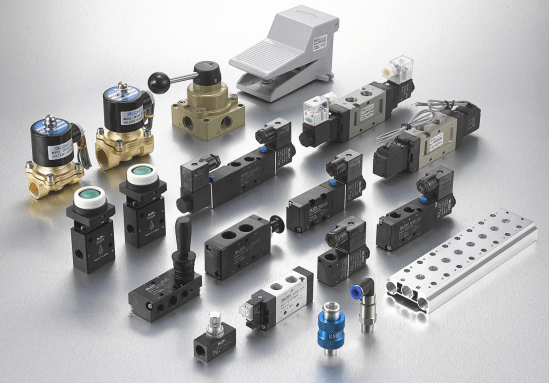

There are different types of solenoid valves, each with different principles of operation:

Direct operated (operating from 0 bar)

Semi-direct operated (operating from 0 bar)

Indirect operated (pressure differential required, normally at least 0.5 bar)

It is important to choose the right operation principle. Direct operated valves operate from 0 bar. In the valve there is a small orifice which is sealed off by a plunger with a polymer gasket. If the solenoid (electromagnet) is electrically energized, the plunger is lifted by the electromagnetic force and the valve opens. This principle is often used for small valves and is suitable for small flow rates. For larger flow rates, a semi-direct or indirect operated valve is recommended. Both make use of the medium pressure to open and close the valve. Semi-direct operated valves operate from 0 bar and often have a more powerful coil than indirect operated valves. Indirect operated valves need a permanent pressure differential of around 0.5 bar for proper operation. The advantage of indirectly operated valves is that they usually can control large flows with a relatively small coil and thereby have a reduced energy consumption.

Check if there is a permanent pressure differential over the valve of at least 0.5 bar. In this is the case, an indirect operated valve may be chosen (a semi-direct valve is of course also allowed in this case). If this is not the case (low inlet pressure, closed circuit, ..), choose a (semi-)direct operated solenoid valve.

from Internet